Introduction

- The

first vapor absorption refrigeration machine was developed by a French

scientist Ferdinand Carre in 1860.

- The

vapor absorption system uses heat energy, instead of mechanical energy as

in vapor compression, in order to change the conditions of refrigerant

required for the operation of the refrigeration cycle.

- In

the vapor absorption system, the compressor is replaced by an absorber, a

pump, a generator, and pressure reducing valve.

- The

refrigerant and absorbent used are sulphuric acid and water, ammonia and

water.

- In

this cycle ammonia is used as refrigerant and water as absorbent.

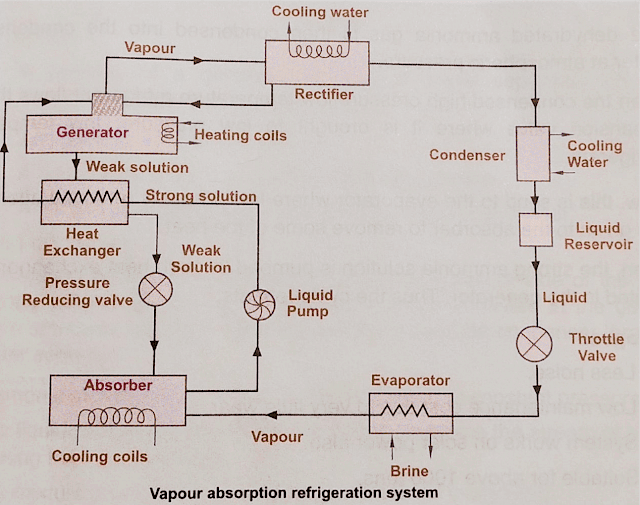

Construction

The ammonia (NH3) absorption refrigeration

system consists of a generator, rectifier, condenser, liquid reservoir, throttle

valve, evaporator, water-jacketed absorber, pump.

Generator: It is the place where the refrigerant and absorbent mixture (weak

solution) is heated using an external heat source such as a heating coil or

by solar energy. The temperature of the solution increases and it is converted

into vapor solution. The high-temperature vapor solution leaves the generator

at high pressure.

Rectifier: Rectifier is used to remove

the water vapor from the refrigerant (NH3) so that water vapor does not enter

the condenser and to avoid freezing at the throttle valve. In the rectifier, the

water vapor is cooled and again recirculated to the generator.

Condenser: A condenser is a device that acts as a heat exchanger in the refrigeration system, which

rejects the heat energy of the refrigerant gas gained in the

generator. Atmospheric air and water are the two most convenient

heat sinks to which heat can be rejected. By rejecting heat to the heat sink

high-pressure high-temperature vapor refrigerant is converted into high-pressure low-temperature liquid refrigerant.

Throttle valve: The Throttle valve is also called an expansion valve or metering

device. Used to expand the liquid refrigerant from the condenser pressure to

the evaporator pressure (to maintain a pressure difference). Also

used to control the flow of liquid refrigerant according to the load on the

evaporator. The refrigerant leaves the throttle valve at low-pressure low-temperature liquid refrigerant.

Evaporator: Evaporator

is a cooling chamber in which products are placed. Low-pressure liquid

refrigerant flows in the coils of the evaporator and absorbs the heat from

products. The refrigerant vaporizes and leaves for the absorber.

Absorber: Absorber is the place

where the vapor refrigerant (ammonia) from the evaporator gets cooled and

absorbed by an absorbent (water). Now the vapor refrigerant gets cooled and it

is converted into a liquid solution of refrigerant and absorbent mixture (strong

solution).

Working principle

- Ammonia

vapor is produced in the generator at high pressure (10.5 bar) from the

strong solution of NH3 by external heating.

- Then,

it is passed into the rectifier where the water vapor is removed by

external cooling water circulation.

- The

dehydrated ammonia gas is then condensed in the condenser by water at

atmospheric pressure.

- Then

the condensed high-pressure low-temperature liquid refrigerant flows through

expansion valve where it is brought to low-pressure low temperature

refrigerant.

- Now,

the low-pressure low-temperature refrigerant is sent to the evaporator

where latent heat is removed after which it is given to the absorber to

remove some of the heat.

- Then,

the strong ammonia solution is pumped through a heat exchanger and is heated in the generator. Thus the cycle repeats.

Advantages

- Less

noise

- Low

maintenance cost due to very little wear.

- System

works on solar power also.

- Suitable for above 1000 tons.

- Less

space is required.

Disadvantages

- Its

efficiency is low.

- It

takes a long time to produce the necessary cooling effect.

- Kerosene

oil or gas flame used for supplying heat energy gives out a bad smell.

Types of vapor absorption system

1. Electrolux refrigerator or absorption system.

2. Lithium bromide- water absorption refrigeration system.

3. Solar absorption refrigeration system.

Waooo

ReplyDelete